Shipping Pallets: An Overview to Their Function in Supply Chain Stability

In the current rapid international environment, the efficient transportation and storage of products is more critical than ever. Essential in this logistics system lies a basic yet significant component: platforms. These sturdy platforms are key to ensuring that items move smoothly through supply chains, between manufacturers, retailers, and finally to customers. Understanding pallets in tulsa of pallets can demonstrate much about their impact on supply chain resilience and logistical efficiency.

Pallets not only facilitate the simple handling of goods but also provide a standardized solution for stacking and storing items in storage facilities and trucks. Their capacity to optimize space and streamline loading processes helps businesses reduce costs and cut transit times. As companies face the challenges of fluctuating demand and supply disruptions, the dependable use of pallets becomes even more vital in maintaining the flow of goods and guaranteeing that operations run seamlessly.

Types of Pallets

Pallet types come in various types, each designed to address specific needs for the transportation and holding of products. One of the most prevalent types is the timber pallet, known for its robustness and strength. Timber pallets are widely used in various industries due to their ability to carry heavy loads and their rough surface, which helps in keeping goods during transit. Additionally, they are often cost-effective and can be readily repaired or recycled, making them a popular choice for many businesses.

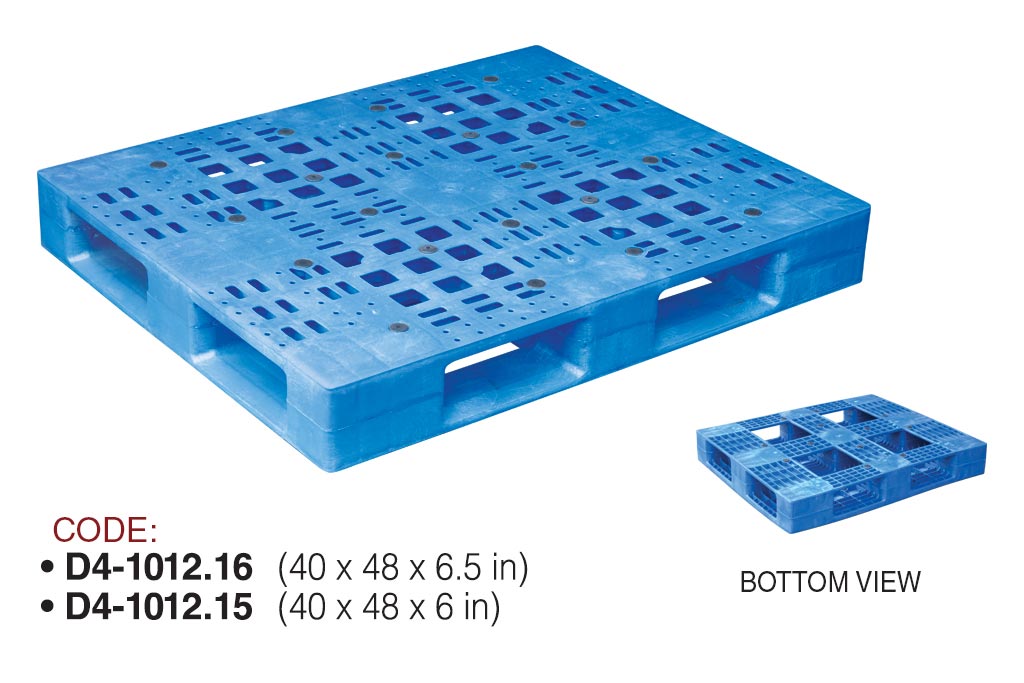

Another prevalent type is the polymer pallet, becoming traction due to its lightweight nature and resistance to moisture, chemicals, and pests. Polymer pallets are particularly advantageous in settings where hygiene is essential, such as the food and pharmaceutical industries. Their strength extends their lifespan beyond that of wooden pallets, and they can be easily cleaned and reused. Although the upfront investment may be higher, the long-term benefits often justify the cost.

Metal pallets, usually made of metal or aluminum, offer an even more durable alternative, especially for heavy-duty applications. Such pallets are ideal for moving and holding bulky items or products that are prone to harm. Their strong design makes them suitable for harsh environments and they often have a longer lifespan than either wood and plastic pallets. Nonetheless, the weight and cost of metal pallets can be a disadvantage for some operations, leading companies to evaluate their particular needs before selecting the appropriate type.

Pallets and Logistics Effectiveness

Effective shipping and storage of products are critical components of a thriving supply chain, and pallet systems play a crucial role in this process. By providing a consistent platform for arranging and moving commodities, pallets facilitate more efficient handling with forklifts and pallet jacks. This uniformity helps reduce unloading and loading times, guaranteeing that goods can move quickly from vendors to retailers or customers. In an increasingly challenging market, the rapid transportation of products is critical for companies to respond to client demand effectively.

Additionally, pallets contribute to maximizing storage space and improving inventory management. When goods are stacked on pallet systems, they can be stored upwards, which takes advantage of warehouse height and optimizes available area. This effective use of capacity allows companies to maintain increased inventory without the need for expanding their facilities, thus reducing expenses associated with storage. Additionally, systematic pallet storage systems make it easier for employees to find and access goods, further enhancing productivity.

Finally, the durability and reusability of pallets support a green supply chain. Made from substances like timber or plastic, pallet systems can handle heavy loads and multiple trips, minimizing the need for regular renewals. This long lifespan not only reduces waste but also lowers procurement costs. By investing in premium pallet systems, businesses can improve their overall supply chain robustness, making sure that products are stored and transported efficiently while also promoting environmentally-friendly practices.

Future Trends in Pallet Applications

As the logistics network continues to transform, the need for cutting-edge pallet solutions is on the rise. Companies are increasingly focused on sustainability, leading to a shift towards eco-friendly materials like reclaimed plastics and sustainably sourced wood. This shift not only meets consumer expectations for eco-consciousness but also helps companies reduce their carbon footprint in shipping and warehousing. The adoption of these materials into pallet production is likely to grow, supporting a more sustainable logistics approach.

Tech advancements is also playing a important role in the future of pallet usage. The incorporation of smart pallets, equipped with sensors and tracking systems, facilitates real-time oversight of goods throughout the supply chain. This development allows for more efficient inventory management, reduces damages due to spoilage, and enhances overall supply chain visibility. As organizations increasingly adopt mechanization and big data, smart pallets are expected to become a norm in modern logistics systems.

Additionally, the worldwide transition towards digital commerce is reshaping pallet use. With the rise in digital retail, the need for optimized and versatile pallet designs is more critical than ever. Organizations are adapting their pallet arrangements to accommodate various sizes and types of products, improving transport and storage efficiency. This adaptability not only enhances operations but also enhances the customer experience by ensuring on-time arrival and product accessibility. The future is likely to see even more tailored solutions that align with the changing needs of the online market.